Precision Vacuum Regulators

Equilibar precision vacuum regulators (EVR) are designed specifically to control a highly stable inlet pressure across widely varying input conditions. The EVR maintains tight control despite variation in supply vacuum or changes in flow rate. Equilibar precision vacuum regulators work differently from traditional vacuum control valve designs. They use a flexible diaphragm as the only moving part. This diaphragm is used to directly seal against the internal valve orifices, eliminating the “stiction” commonly found in traditional vacuum control valves that rely on dynamic O-ring or wiper-type seals. The Equilibar design is frictionless and can control a vacuum with very high resolution.

1/2" EVR-GDS4 with Manual Pilot Setpoint Adjuster - Equilibar lower flow precision vacuum regulators are available in sizes ranging from 1/4″ to 1″ with material options of stainless steel 316/316L, anodized aluminum or PVC depending on the application requirements for temperature and chemical resistance. Each EVR is delivered with a manual pilot setpoint regulator for convenient knob adjustment.

Equilibar’s precision high flow vacuum regulating valves (EVRs) offer unique performance advantages for pipe sizes up to 4″ in size. EVRs are made in two form factors in this size range – The EVR-IC Industrial Collection and the EVR-BD Series – each with their own benefits. The best choice will depend on the application requirements, which you can discuss with our application engineers.

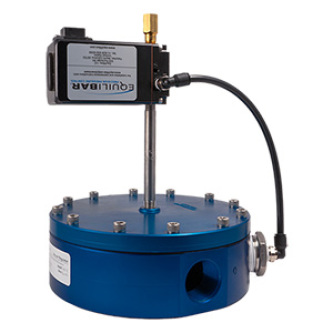

Equilibar 4″ EVR-BD32 vacuum regulator with PVC body and manual pilot setpoint control-Our precision high flow vacuum valves are available in sizes ranging from 1 1/2″ to 4″ with material options of stainless steel 316/316L, anodized aluminum or PVC depending on the application requirements for temperature and chemical resistance. Each EVR is delivered with a manual pilot setpoint regulator for convenient knob adjustment. Electronic pilot regulators can be purchased if automating the EVR is your preference.

Electronic vacuum regulators allow vacuum control through a computerised command signal. The command signal is first sent to a small electronic regulator that produces a pilot signal to the reference port of the dome-loaded Equilibar Vacuum Regulator (EVR) to control the process pressure.

Equilibar offers a line of precision electronic pressure regulators to provide this pilot reference signal. The QPV ultra-resolution and the EPR-30Hg models have virtually no hysteresis or deadband, resulting in the capability to make precise adjustments.

These regulators can be used in open loop mode or closed loop mode. In open loop mode, the vacuum setpoint is commanded using a computerized signal sent to the electronic pilot regulator. The pilot regulator produces that commanded pressure onto the EVR reference port to keep the process vacuum very close to the setpoint value. Open loop mode will result in a slight variability in vacuum pressure as flow rates increase.

In closed loop, or PID mode, the process vacuum pressure is monitored by a separate pressure sensor close to the process, and the command signal sent to the pilot regulator is adjusted to bring that process pressure to match the desired setpoint. This PID action can be accomplished inside the QPV electronic pressure regulator, or in the existing process control system. Closed loop control will result in more accuracy over a wide range of flow rates.

Interested

To discuss our extensive range of products and systems, or your application

email: sales@proportionair.eu

email: usa-sales@proportionair.eu

UK: +44 (0) 2477671600