Data-Centres

In recent years, investment in data centres has seen tremendous growth. The widespread adoption of AI and the move towards more remote work post-pandemic have created a higher demand for various cloud services, web hosting, software, and other services provided via data centres. Cooling infrastructure within these data centres, in particular, is a rapidly growing market.

Why are data centre cooling systems important?

Data centres have many racks of servers, containing many processors. This produces vast amounts of heat. Computer components are negatively affected by excess heat; processors will throttle in

performance as temperature increases. If the temperature exceeds a certain value, individual components may begin to fail. Failed components create unplanned downtime or service outages and require

higher capital expenditure over time due to the replacement of hardware. Cooling systems are therefore necessary to keep data centres functioning.

At the same time, cooling systems consume massive amounts of energy, often accounting for between 30-50% of a data centre’s overall energy consumption. A balance must be

struck in designing the most efficient data centre cooling system such that component failures are minimised while also minimising unnecessary power consumption.

Common methods of data centre cooling?

Data centre cooling technologies include using two-phase refrigerants, liquid and air.

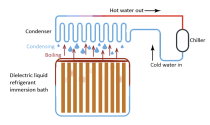

Data centre cooling with two-phase refrigerant

The most common cooling method using two-phase refrigerants is data centre immersion cooling. With immersion cooling, the entire data centre server rack is immersed in a tank of dielectric liquid

refrigerant.

Data centre liquid cooling

There are three main methods of data centre liquid cooling systems

1. Immersion cooling – As with the two-phase cooling setup shown above, liquid immersion systems submerge the entire server within a bath of a dielectric fluid. With a single-phase fluid however, heat must be pulled out of the rack via a coolant distribution unit (CDU), where a pump moves the fluid across a heat exchanger for final heat rejection. That heat can then be managed via traditional means – chilled water loops, evaporative cooling systems, etc.

2. Spray cooling – Similar to cold plate DTC cooling, spray cooling is done at a per-component level within the rack. A manifold of nozzles within the rack is set up to spray a dielectric liquid at specific components (CPU, GPU, etc). That dielectric fluid drips down into a collection system and is circulated via a small pump through a loop where the heat is transferred out to the building’s water loop via a liquid-to-liquid heat exchanger.

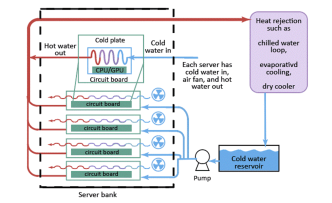

3. Cold plate cooling – liquid cooling is circulated across specific components that produce the most heat, typically CPUs/GPUs, via a metal cold

plate.

Cold water is circulated through the loop where it absorbs heat from these server components, then flows out of the server to a central hot water return for heat rejection. It’s common for these systems to also use fans as well to provide some degree of air cooling for the other components within the server. Direct to chip (DTC) is a general term for systems like this, where cooling is done at the chip level (as shown above with a plate on the CPU/GPU)

Why choose Equilibar® valves for data centre cooling systems?

The unique design of Equilibar back pressure regulators and control valves offers many benefits for a variety of different liquid and two-phase cooling

systems.

Wide operating Cv turndown – Equilibar back pressure and control valves are capable of a minimum 100:1 Cv turndown ratio. In order to accurately maintain the temperature of the coolant, fluid flow and pressure must be precisely controlled. In systems with multiple points-of-use where varying flows are typical (as you would see with in-rack or in-row cooling), there can be a wide variation in the instantaneous flow demand through the main recirculation line. With traditional control valves, the wide flow rate demand may require multiple valves to cover the entire flow range, where a single Equilibar valve will suffice.

• Ease of automation – Equilibar valves are dome-loaded with a pilot pressure regulator controlling the setpoint. They can be controlled using an

electronic pilot regulator, allowing for easy integration with automated control systems. Equilibar valves can modulate Cv in response to either flow, pressure, or temperature-based feedback.

• Customisation for varying service conditions – The simple design of Equilibar valves makes customisation with various materials of construction easy for compatibility with liquid

and two-phase refrigerants while still retaining the same performance.

• Two-phase refrigerant control – Equilibar valves are uniquely suited for many challenges found within two-phase refrigerant systems. The unique multi-orifice design allows for

stable pressure or flow control with mixed-phase liquid gas conditions.

Interested

To discuss our extensive range of products and systems, or your application

email: sales@proportionair.eu

email:usa-sales@proportionair.eu

UK: +44 (0) 2477671600

USA: +1 (973) 224-6288