Biogas generator benefits from precision pressure control

Anaerobic digestion

(AD) is a biological process in which biodegradable organic matters are broken down by bacteria into biogas consisting of methane (CH4), carbon dioxide (CO2), and other trace amounts of gases. The biogas produced during this process can be used to generate heat and electricity. The primary requirement for AD is an environment absent of O2. Other important factors, such as temperature, pH, moisture and nutrient contents, are also critical for the success of AD. Electricity can be generated on-site of an anaerobic digester using a reciprocating engine, steam turbine, or gas turbine.

Application

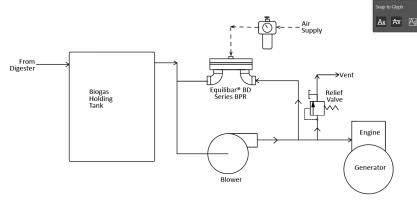

Many wastewater treatment plants use anaerobic digestion to process their biological solid wastes, reducing landfill volumes and generating valuable electricity in the process. Controlling the biogas pressure that feeds the combustion engine is critical, especially because the flow rate coming out of the digester fluctuates. A precision back-pressure regulator can be used to effectively control the biogas pressure while circulating excess gas back to the digester for reuse.

Precision low-pressure regulators

Back pressure regulators (BPR) work similarly to relief valves, but the emphasis is on steady state pressure control instead of on/off pressure protection. The Equilibar back pressure regulator incorporates a dome-loaded design and uses multiple parallel orifices sealing against a supple diaphragm to better maintain pressure stability. The dome loaded design uses compressed air to load the internal diaphragm rather than a coil spring used in traditional designs. The advantage is that the supple diaphragm responds instantaneously to setpoint changes and process variations to achieve a precise pressure control.

The setpoint is determined by a small manually operated or electronic pilot regulator (not shown) supplied with filtered shop air. The controlled pressure (4 psig for example) can be adjusted to achieve optimum performance from the engine-generator system.

Stable perfomance

The installation of a 'BPR' provides a much more precise pressure control in the range required by the generator. A quick acting safety relief valve installed in parallel only comes into play in rare instances of excess pressure above a higher set point. With the system pressure now smoothly controlled by the 'BPR' and only the over pressure relief function assigned to relief excess pressure, the more commonly installed reducing regulators can be removed from the circuit.

Interested

To discuss our extensive range of products and systems, or your application contact us on:

email: sales@proportionair.eu

emai.l:usa-sales@proportionair.eu

UK: +44 (0) 2477671600